Machining Plastics: Case Study Polysulfone

- Pedro Henriques

- Feb 17, 2022

- 11 min read

In this Series of discussions, we will explore some past projects that involved some trouble shooting and some machining tips that were learned along the way. This might help you set your mind when certain problems arise in your next project.

PSU 1000: Case Study

In this study we are going to talk about Polysulfone materials and where we used them. PSU1000 is great for hot water and steam performance, broad temperature range capability with good thermal and electrical insulation characteristics. Hydrolysis resistant, radiation stable with low ionic impurity makes this an excellent replacement for Acrylic, Nylon and stainless steel. We have used this material with great success for the pharmaceutical, medical, food service equipment, semiconductor processing, and electronic equipment industries.

Tecason® S: Is a transparent engineering plastic known for its chemical resistance, rigidity, high-temperature, and its ability to operate in an autoclave environment. Tecason® S is FDA and NSF compliant and holds its excellent mechanical properties over a wide range of temperatures. Excellent electrical properties and good chemical resistance to mineral acids, alkali, salt solutions, and hydrocarbons. Tecason® S has a heat deflection of 345°F and long-term continuous use of 285°F. Excellent hydrolytic stability, high strength and flame retardant rating of UL94 V-O. Tecason® S unique combination of the listed properties and agency approvals make it an excellent choice for pharmaceutical, medical, food service equipment, semiconductor processing, and electronic equipment industries.

Udel® P-1700: Is transparent and slightly yellow tough, rigid, high-strength thermoplastics suitable for continuous use up to 300°F (149°C). It is resistant to oxidation and hydrolysis and withstands prolonged exposure to high temperatures and repeated sterilization. Udel P-1700 Polysulfone is highly resistant to mineral acids, alkali and salt solutions. Resistance to detergents and hydrocarbon oils is good, but the resin may be attacked by polar solvents such as ketones, chlorinated hydrocarbons and aromatic hydrocarbons. These resins are also highly resistant to degradation by gamma or electron beam radiation. Electrical properties of Udel P-1700 Polysulfone are stable over a wide temperature range and after immersion in water or exposure to high humidity. The resins comply with FAR 21 CFR 177.1655 and may be used in articles intended for repeated use in contact with foods. Additionally, they are approved by the NSF, by the Department of Agriculture for contact with meat and poultry and by the 3-A Sanitary Standards of the Dairy Association. - Transparent: Udel P-1700 CL 2611 CMP - Transparent: Udel P-1700 NT 06 - Transparent: Udel P-1700 NT 11 - Opaque Black: Udel P-1700 BK 937 - Opaque White: Udel P-1700 WH 6417 - Opaque White: Udel P-1700 WH 7407. The glass-reinforced grades offer higher stiffness and dimensional stability, with attendant benefits in creep resistance, chemical resistance, and lower thermal expansion.

Common Applications for Udel P-1700:

Appliance Components

Automotive Electronics

Dental Applications

Electrical parts

Electrical/electronics

Food service applications

Hospital goods

Industrial parts

Medical appliances

Medical/Healthcare

Microwave cookware

Piping

Plumbing parts

Surgical instruments

Valves/Valves parts

Printer cartridges

Machining Udel P-1700:

Udel resins may be machined with normal metal working tools. Because of their high softening temperatures, relatively high cutting speeds can be used without gumming. However, where low stress in finished parts is desired for hydrolytic stability or chemical resistance, slower speeds and very sharp tooling are suggested. The slow speed, sharp tool approach develops less heat in the machined surface resulting in lower stress. All machining operations cause some increase in stress and, depending on the environment to be encountered in end use, annealing of the finished part may be necessary. If coolants are needed, plain water can be used. Most machining coolants for metal should not be used because they are incompatible with Udel Polysulfone. One commercial coolant that is, when used at recommended concentrations, compatible with Udel Polysulfone is Cimcool® Cimtech® 95 from Milacron Marketing.

PSU 1000: is an amber semi-transparent, heat resistant, high performance engineering thermoplastic. It offers excellent mechanical, electrical and improved chemical resistance properties relative to polycarbonate. Polysulfone’s properties remain relatively consistent over a broad temperature range, from –150°F (–100°C) to 300°F (100°C). PSU 1000 Polysulfone is hydrolysis resistant for continuous use in hot water and steam at temperatures up to 300°F. Its flame resistance is UL 94-V-0 at 1/4” thickness (6.35mm) and UL 94-V-2 at 1/8” thickness (3.175mm). PSU 1000 Polysulfone offers high chemical resistance to acidic and salt solutions and good resistance to detergents, hot water and steam. In addition, Polysulfone has excellent radiation stability, and offers low ionic impurity levels. PSU 1000 Polysulfone often replaces polycarbonate when higher temperatures, improved chemical resistance or autoclavability is required (See Figure 14). It is commonly used for analytical instrumentation, medical devices and semiconductor process equipment components. Food-grade PSU 1000 Polysulfone and custom colors can be special ordered. Only food-grade PSU 1000 is FDA, NSF, 3A-Dairy and USP Class VI compliant.

Common Applications for PSU:

Manifolds

Medical equipment components

Steam cleaning equipment inserts

Distributor Valves

Food Processing equipment

Aircraft instrumentation

Sensors and Sight glasses

Appliances

Life science applications

Electrical components

Float switches

Solenoid valve body

Catering trolleys and trays

Pump parts

Bushings and Gears

Note: Polysulfone is not a wear material and may stress craze under high pressures in certain chemical environments.

Machining PSU 1000:

Coolants are generally not required for most machining operations (not including drilling and parting off). However, for optimum surface finishes and close tolerances, non-aromatic, water soluble coolants are suggested. Spray mists and pressurized air are very effective means of cooling the cutting interface. General purpose petroleum based cutting fluids, although suitable for many metals and plastics, may contribute to stress cracking of amorphous plastics such as Quadrant PC 1000, Quadrant PSU, Duratron® U1000 PEI, and Quadrant PPSU.

Sawing Tip: Rip and combination blades with a 0° tooth rake and 3° to 10° tooth set are best for general sawing in order to reduce frictional heat. Use hollow ground circular saw blades without set will yield smooth cuts up to 3/4” thickness. Tungsten carbide blades wear well and provide optimum surface finishes.

Drilling Tip: Coolants are strongly suggested during drilling operations, especially with notch sensitive materials and glass or carbon reinforced products. The insulating characteristics of plastics require consideration during drilling operations, especially when hole depths are greater than twice the diameter.

Milling Tip: Sufficient fixturing allows fast table travel and high spindle speeds when end milling plastics. When face milling, use positive geometry cutter bodies. Climb milling is recommended over conventional milling. To ensure finished part flatness, always machine a plate flat to start. Do not force a plate flat with a vice or vacuum.

Threading and Tapping Tip: Threading should be done by single point using a carbide insert and taking four to five 0.001” passes at the end. Coolant usage is suggested. For tapping, use the specified drill with a two flute coated tap. Remember to keep the tap clean of chip build-up. Use of a coolant during tapping is also suggested. Use of a coated tap will create radii at the root of the threads resulting in a stronger and tougher thread which is less prone to cracking from over-torquing.

Turning Tip: Turning operations require inserts with positive geometries and ground peripheries. Ground peripheries and polished top surfaces generally reduce material build-up on the insert, improving the attainable surface finish. A fine-grained C-2 carbide is generally best for turning operations.

Finale Note: Proper feed rates are most critical to ensure reduced heat generation, tolerance control and good surface finish. Machining speeds can be increased above those listed as long as recommended feed rates are maintained.

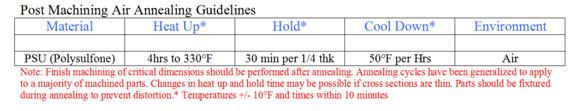

Post Machining Annealing: In our experience and parts we have produced this step was avoidable with a roughing in machine stage and leaving parts unclamped for 1 to 2 days. This worked great for critical tolerance work. Here is some information on the annealing process that we feel is important to at least mention.

1. WHEN SHOULD PARTS BE ANNEALED AFTER MACHINING?

Experience has shown that very few machined plastic parts require annealing after machining to meet dimensional or performance requirements. Most Quadrant stock shapes that we used are annealed using a proprietary stress relieving cycle to minimize internal stresses that may result from the manufacturing process. This assures that the material will remain dimensionally stable during and after machining. However, machined-in stress can result in poor tolerance control and premature part failure. To prevent machined-in stress, it is important to identify the causes. Machined-in stress is created by:

Using dull or improperly designed tooling

Excessive heat generated from inappropriate speeds and feed rates

Machining away large volumes of material (usually from one side of the stock shape)

ROUGHING - RECOMMENDED ANNEALING TECHNIQUE: A simple rough machining step is usually sufficient, and preferred over oven annealing, on almost all jobs to achieve even the most critical tolerances on final dimensions. When machining with a mill, rough the parts leaving 0.030” to 0.060” per side. For rounds, rough the diameter oversized by 0.125”. Once rough machined, let the parts sit for 24 to 48 hours to stabilize; then finish machine. The more material you need to machine away, the more material you should leave on during roughing. Also, balanced machining on both sides of the shape centerline should be followed during roughing to help prevent warpage.

2. WHEN SHOULD PARTS BE OVEN ANNEALED?

Post machine oven annealing may provide additional performance benefits in a few rare cases. Also, oven annealing is used by some to achieve extremely tight tolerances. If using an oven be sure to follow annealing guidelines below, as shortcuts will actually increase part stress and create more problems holding required dimensions. Oven annealing may be used for the following rare cases.

Tighter Tolerance Capability: For extremely close tolerance parts, sometimes rough machining alone is not sufficient. Close tolerance parts requiring precision flatness and non-symmetrical contour sometimes require intermediate oven annealing between machining operations.

Case Study #: Sterilization and Chemical Attack of Acrylic, Stainless Steel, Nylon

Customer was looking for a material to replace several materials that where cracking from the various sterilization processes that are required as a scheduled maintenance requirement in this medical machine. The what and how this equipment worked or its function was not disclosed or talked about, customer just showed us the components and there working environment and what was happening. Cost here was not a factor although it helps, what is important is increasing the life and use of the following components. We did manage to get permission to show the cad models that we designed and machined to help improve and replace the troubled components. We can not however show the placement of these various parts in an assembled illustration nor their respective specifications. We are dealing with five (5) different components that under go several different cleaning processes require to fully sterilizing various areas of this unit.

First part is a Nylon Distribution Oil Fluid Pan. This complicated part contained heated fluid, filters, solenoid valves, temperature and level sensor ports, gears, internal pump with various channels and ports through this single part. This part does contain various assemblies and attaches to a larger assembly that we did not see. Several functions of concern to us were the chemical and steam port channels that were built in to perform a self-cleaning or sterilization cycle. During this cycle there are one-way valves that open to push chemicals, hot water and steam throughout various locations. This would explain the chemical attack and heat damage on the nylon material. Nylon can be heat stabilized and resist temperatures up to 260°F but it is best suited for wear applications, and this nylon in question was not a heat stabilized grade.

Before moving on a critical function to this machine is something called Hydrolytic Stability, what is this? Hydrolytic stability can be defined as resistance to hydrolysis, or attack by water, especially hot water. Therefore, hydrolytic stability is a specific instance of chemical resistance. Hydrolytic stability has special importance because water is ubiquitous and is very aggressive to many polymers. A Hot Chlorinated Water was also used, why is this important? Because residual chlorine in water systems combined with elevated temperatures can produce an oxidizing environment, resistance to hot water is not always enough. Since many plastics are susceptible to oxidation and oxidizing agents, this condition can dramatically shorten the service life of components made from some plastics.

Let's move on to the Layer Manifold that distributes various fluids to various metered locations. This multipart manifold is currently made of Acrylic discs that are bonded together to form various o-ringed ports and distribution channels. There are heated fluid channels, cooled fluid channels, low and high pressure channels all handled by this part. This part is only chemically sterilized during the cleaning cycle and due to the fluids inside this manifold a sterilized by radiation process is performed at some point and the part is often getting cracked from handling and environmental stresses.

What is Radiation Sterilization: Methods of sterilization using radiation such as gamma rays, electron beams, X-rays, ultraviolet light and subatomic particles. Gamma rays have high penetration and are frequently used for sterilization of disposable medical equipment, such as syringes, needles, cannulas and IV sets in their final packaging. Gamma irradiation requires bulky shielding for the safety of the operators and safe storage of the radioisotope from which the gamma radiation is emitted. Besides electromagnetic irradiation with gamma rays, particle radiation can also be used for sterilization. The best-known form is radioactive beta radiation, which results in the release of energy-rich electrons. Compared to gamma, it has less penetration and a reduced detrimental effect on material properties. However, specialty materials are regularly used. We will not discuss the other mentioned forms of radiation sterilization since they are not used in this application.

Note: Not all materials can handle this process especially repeated cycles over time, be sure to fully research and test your materials before a final part is considered and used for your application.

Next is the Distributor Valve block made of stainless steel that is used to control the valves that open and close during the chemical, hot water and steam sterilization process. There are several senor ports, solenoids and a temperature senor that mount to this part. This block connects to several Blood Chamber Blocks (also made of stainless steel) and are located elsewhere on the machine.

The Blood Chamber Block and Cap have multiple ports for temperature and level sensors with various electronic housings mounted to the outside portion of the block. These blocks have to endure repeated autoclaving cycles before and after use since they are exposed to blood. In a sense this machine is able to autoclave its internal parts, but the parts are also externally autoclaved at some point. We should at this point discuss autoclaving process and why, for those that are not familiar with this term or process.

What is Autoclaving: Sterilization (or sterilisation) is a term referring to any process that eliminates (removes) or kills all forms of microbial life such as fungi, bacteria, spore forms, etc., present on a surface, contained in a fluid, in medication, or in a compound such as culture media. Decontami-nation by autoclaving is the reduction of contamination to a level where it is no longer a hazard to people or the environment. Steam sterilization is moist heat sterilization which is one mode of sterilization. Moist heat, as the name indicates, utilizes hot air that is heavily laden with water vapor and where this moisture plays the most important role in the process of sterilization. Moist heat causes destruction of micro-organisms by denaturation of macromolecules, primarily proteins. Destruction of cells by hydrolysis may also play a role. Steam Sterilization is the most commonly used sterilization method in the world which is achieved by using the Instrument Autoclave / Converter / Steam sterilizer.

Why Autoclave: A body penetrated by disease-causing microorganisms is said to be "contaminated". Instruments used during an operation are also considered to be contaminated by the patient’s microorganisms and pathogens. If these instruments are not scrupulously cleaned and sterilized before being used on another patient, pathogens can be passed from one patient to another. Blood and body fluids can cause pitting on instruments, component ports and channels or surfaces and if left to dry, can be difficult to remove.

Note: The sterilization of materials using steam and pressure is a dependable procedure for the destruction of all forms of microbial life. However, the autoclave must be properly used and understood to be effective. Do not assume that merely pushing the button on an autoclave will result in the proper sterilization of your materials! Not all materials can handle this process especially repeated cycles over time, be sure to fully research and test your materials before a final part is considered and used for your application.

Challenge: Replace failing Nylon Distribution Oil Fluid Pan, increase the life and durability of the Layer Manifold and replace the costly stainless steel Distributor Valve block, Blood Chamber Block and Cap with a material able to withstand multiple autoclave cycles.

All trademarks and service marks are property of their respective manufactures. All statements, technical information and recommendations contained in this publication are presented in good faith and are, as a rule, based upon tests and such tests are believed to be reliable and practical field experience. The reader, however, is cautioned that Diversified Designs does not guarantee the accuracy or completeness of this information and it is the customer’s responsibility to determine the suitability of any information provided by Diversified Designs in any given application.

Comments