Project of the Week of 04/07/07

- Pedro Henriques

- Jul 30, 2022

- 1 min read

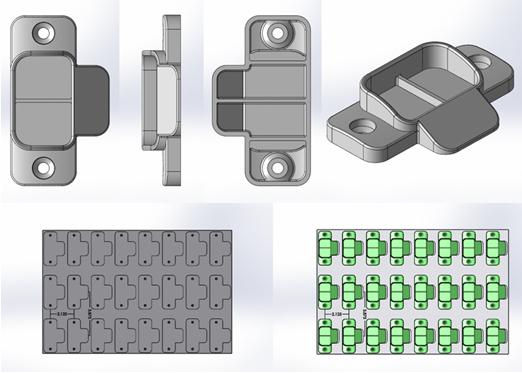

Project of the week is a Door Latch Sensor Housing machined from High Impact Polystyrene. This part was eventually injection molded once tooling was done, but we handled the first initial orders that spanned over 6 weeks. This part is roughly 3-1/2 x 2" x 1-1/8 with a typical 0.080 wall. This part is used on a machine door that not only locks but senses if the latch is not properly secured. Top area of this part contoured and had to be 3d milled and blended. We machined a fixture to hold and position 24pcs per cycle for a lot run of 2000pcs.

End Mills, Ball Mills, Corner Round Mills and Chamfer Mills were solid carbide from Premium Carbide Tool with standard High-Speed Drill and Countersink. We used Mic6 aluminum plate for a total of 2 fixtures in order to stage and hold down the latch while one batch was being machined. Overall part tolerance was +/- 0.015 the machine finish with round edges was tumble finished to create a slight texture and helped to smooth out the 3d tool paths. Nice project to start the week of 04/07/07, we would like to thank our customer for allowing us to share this one project with people who value the manufacturing talent that is out there... If you have similar projects like this and would like to receive a quote from us, please reach out to us for further information.

Comments